Assessing And Lowering the Danger of an Arc Flash Is Crucial:

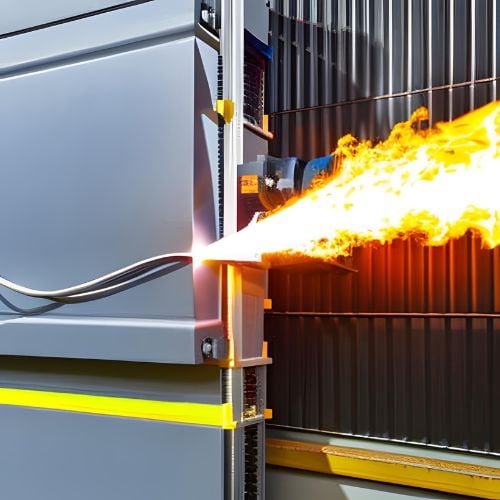

Electrical arcs arise when a gas is subjected to a voltage greater than its insulating qualities. When the voltage is strong enough to ionize the air between the conductors, the arc is initiated. When a gas is ionized, it turns into an excellent conductor, enabling current to flow and creating the arc-shaped current known as arc flash.

Air ionization produces a current that creates heat and dazzling light. This heat causes the ionized air to ascend, creating an arch-shaped current, hence the phenomenon’s name. An arc flash can produce temperatures up to 20,000 degrees Celsius.

Arc flash dangers endanger both humans and property. Among the commercial impacts of arc in flash are:

- Direct expenses are medical care, rehabilitation, worker compensation, and the cost of accident investigation and productivity loss.

- Indirect expenses include legal and judgement costs, litigation costs, penalties, insurance premiums, repair charges, and replacement worker costs.

- Your personal reputation, your capacity to compete on the job market, and the prospect of criminal charges are affected by negative effects.

- Most clients reject businesses with high incident rates, resulting in missed business prospects and potentially the revocation of an electrical contractor’s license.

- Mishaps involving an electrical circuit Flash tend to create an impression, resulting in missed chances and wasted income.

Causes of Arc Flash Danger:

- Using the probe on the incorrect surface

- Inappropriate equipment, installation, and procedures

- Using defective electrical components

- Insulation damage or equipment gaps

- Disconnect panel interference

- Electrical equipment dust or rust

- Improper maintenance of circuit breakers and switches

- Live components or fraying connections

- High voltage wires or a steady source of electricity

- Electrical equipment moisture

Arc Flash Hazard Mitigation Methods:

Turning Off Electrical Components:

It minimizes potential dangers to the maximum degree feasible. Work on energized equipment should be avoided, and special caution should be exercised while testing or re-energizing de-energized equipment. Circuit breakers are kept away from arc flash boundaries, which might threaten their operators, using remote tracking technology.

Utilize Low-Risk Technology:

To detect the dangers associated with short circuits and protective device coordination, arc flash analysis and power system investigations are undertaken. Utilize low-threat solutions, such as remote rack equipment, to protect individuals and property.

Electrical and Control System Redesign:

Ensure that the degree of PPE (personal protective equipment) required by the arc flash hazard category is accessible. To lessen hazards, engineering equipment and procedures are being changed. Breakers and energy distribution systems are designed to limit incident energy.

Reduce the Level of Available Fault Current:

Non-current limiting circuit breakers will help industry to lower fault current availability. These devices can be utilized with an open tie for maintenance. Opening the connection between dual power feeds during maintenance decreases arc flash threats by decreasing available fault current. Current limiting reactors can be used to establish a bottleneck in the flow of electrical current, effectively preventing the flow of current during arc faults.

Change the Blaster's Energy:

Promote arc-resistant materials. Arc-resistant switchgear employs sealed joints, top-mounted pressure relief vents, and strengthened hinges to direct arc flash energy and heat through ducts to an unoccupied area. CareLabs conduct exhaustive arc flash analysis. To update your safety program, professionals evaluate arc flash hazards. CareLabs can find and implement modern arc flash risk prevention strategies. CareLabs can research and implement innovative technology for arc flash hazard reduction. CareLabs utilize ETAP (Electrical Transient Analysis Program) software for research and analysis.

We engage crew members in several places to guarantee that our knowledge is readily available in regular and emergency situations. We achieved ISO 9001:2008 accreditation and devoted customers rapidly. Lima, Arequipa, Trujillo, and Chiclayo, and Salvador are Peruvian cities.