Hong Konger Arc Flash Analysis: A Comprehensive Guide

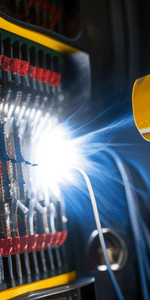

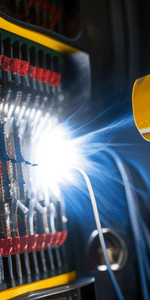

When a gas is exposed to a voltage greater than it can block, electrical arcs form. The arc begins to develop when the voltage is high enough to ionize the air between the conductors. When a gas is ionized, it becomes an excellent conductor, allowing electricity to flow and producing an “arc flash.” A fault arc is an unintended electrical discharge.

- Extremely elevated temperatures cause an arc flash, which creates dazzling light and a loud roar.

- An arc blast is a high-pressure wave that may propel molten metal and metal fragments into the air.

- Poisonous vapors

Arc flash dangers have the capacity to cause severe damage to companies and electrical infrastructure. Listed below are some of the business losses caused by arc flash hazards.

- Additional expenses associated with medical treatment, therapy, workers’ compensation, accident investigation, and production downtime.

- Included in the costs associated with litigation are court fees, penalties, insurance premiums, repair expenses, and the cost of recruiting a new employee.

- A negative impact on the name and reputation of the firm.

- The loss of economic potential caused by a history of accidents, which might result in the revocation of an electrical license.

Table of Contents

Why Do Arc Flashes Occur?

- Insulating damage to the conductor.

- Visible elements of a person’s body

- Human irresponsibility

- Poorly maintained switches and circuit breakers

- The equipment is located close to the water.

- Disconnect any panels that are in the way.

- Elevated-voltage conductors

- Static electricity discharges defective equipment and tools.

Arc Flash Assessment Technique:

Arc flashes can occur anywhere high voltage or low voltage with a high current is switched.

Determine the probability of an arc flash:

- Perform an arc flash/fault analysis or study, including data collecting, software modelling of the power system, analysis of short circuits, examination of interactions between overcurrent protection devices, analysis of arc flashes, and assessment of arc flashes.

- Calculating the likelihood that a worker may be injured by an arc flash

Control the risk:

- Employees are less likely to get arc flash accidents if they only handle equipment that is turned off.

- Manual systems would be inferior to automated ones.

- Install physical barriers between personnel and machinery to safeguard their safety.

Control of processes by engineers:

- Reduce the fault current to lessen the incident energy.

- Systems for arc flash detection and prevention

- Modifications to the management of switches and remotes or switchboard upgrades

- Circuit breakers that are immobile

- Ensure that the bus bars are insulated.

- Purchase replacement fuses for any that have blown.

Administratively imposed safeguards:

- Determining the outside border of an arc by labelling plants, switch rooms, and other crucial locations where energy levels vary.

- Arc flash diagrams and research notes.

- Implementing security principles and methods to reduce exposure

- Using PPE (Personal Protection Equipment) levels and incident energy

Equipment for personal protection (PPE):

- Even though PPE is the least effective kind of protection, it can minimize the severity of an accident, but it cannot prevent one. The type of personal protection equipment (PPE) utilized varies on the level of hazard.

CareLabs can assist you with any issues linked to arc flash. Professionals with in-depth training and understanding can identify arc flash dangers and implement the most effective mitigation and management strategies to protect your workers and property.

Advantages of Carelabs's Offerings:

- Energy systems that are safer and more compatible with regulatory regulations.

- Integrated electrical systems save money and time.

- Enhance the safety of the workplace.

- Provide choices for emergency situations.

- Increase the margins of safety

- Automate the creation of arc flash labels and work permits to save time.

- Avoid potential penalties and legal expenses.

This recommendation is based on what is known about the dangers of electric arc flashes and what has been done to mitigate them. It follows the control approach for dealing with arc flashes. It presents several methods for preventing arc flashes, such as turning off electrical equipment, employing infrared thermography, racking, etc. To ensure that the staff is available for both normal chores and urgent events, CareLabs employs crew members in a range of locations. CareLabs quickly attained ISO 9001:2008 certification and cultivated a customer with a stellar reputation. Arc flash testing and analysis are available from CareLabs in all significant cities, including Hong Kong Island, Kowloon, the New Territories, and Lantau Island.

RELATED NEWS

Coordination

RELATED NEWS