What is it?

Power quality analysis checks the power supply for safety and efficiency.

Years of experience?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus

Terms of service?

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus,

Electrical Standards

RED

RED

LRED

RED

RED

LRED

LRED

RED

LRED

RED

LETS DISCOVER MORE

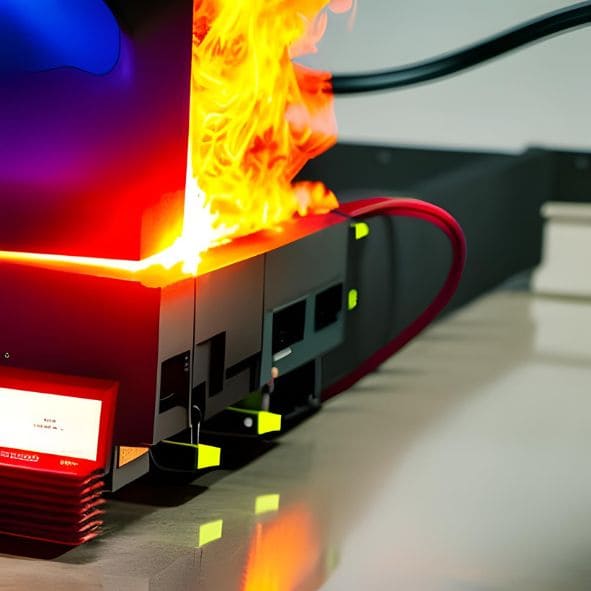

CareLabs provides priced electrical arc flash analysis, investigation, and certification services to businesses of all sizes. To ensure that your electrical safety program is current, compliant, and comprehensive, certified professionals will analyze arc flash hazards, employee training, documentation, and PPE (Personal Protection Equipment) requirements. CareLabs can instantly identify arc flash threats and reduce the impact of harmonic distortions to safeguard the equipment. ETAP (Electrical Transient Analysis Program) software is utilized to investigate and evaluate Arc flashes. The amount of light and heat generated by an arc fault, also known as an arc flash. Something occurs when current flows across an air gap between conductors. The arc flash ionizes the atmosphere and produces a substantial amount of heat and light (approximately 35,000 degrees Fahrenheit). As part of an arc flash analysis, the electrical installations of a facility are studied and assessed to determine the incident energy available for each piece of electrical equipment. Arc flash studies enhance workplace safety by defining criteria for qualified electricians to follow when operating equipment and circuits. Included as well are a short circuit and coordination analysis, new electrical one-line schematics, and equipment placements.

Objectives of Arc Flash Research:

- Determine how much damage was inflicted by the incident energy discharged by an arc flash fault.

- modifying the settings of protective equipment to minimize exposure to incident energy

- Describe the risks posed by arc flash safety regulations.

- Respect the country’s specific laws and regulations.

- Determine the type of PPE being used at work.

The Adverse Consequences of Arc Flash:

- Arcs produce severe facial, ocular, and skin burns.

- Inhaling gases and heated particles can severely burn the throat and lungs.

- Flying debris and unprotected parts cause injury.

Arc flash studies are essential for reducing hazards and enhancing the safety of electrical employees and the entire organization. Arc flash investigations assist in identifying electrical hazard levels and implementing the appropriate safety measures to reduce the risk of accidents and burns. All utilities, manufacturing, industrial, and commercial companies employing important electrical components such as electrical disconnects, motor controllers, panel boards, and switches are required to undertake arc flash studies.

Advantages of Arc Flash Study :

- Increased human and mechanical safety

- Lower medical and legal service expenses

- Compliance with legal and safety regulations

- Fewer rule violations and penalties.

Following are the techniques for doing an arc flash analysis:

- Collection of data

- Conducting a field inspection of a system’s design

- Investigating arc flashes

Work Process in CareLabs in the Arc Flash Research:

CareLabs provides superior services and will fulfil any requirements made by the engineering firm, the construction team, or the local contractors.

The following steps constitute our approach of work:

- Data collection

- ETAP modeling of a power system

- Short-circuit research

- Coordination of overcurrent protection devices: a study

- Investigating arc flashes

- Investigating arc flashes

- Maintaining records

Techniques for lowering the danger of an arc flash:

- One-line diagrams that are large

- Arc flash labeling installation

- The finished document

CareLabs' Services Offer Several Advantages:

- Improve the compliance and safety of electrical systems.

- Integrated modules are linked with protective equipment and bus ratings for comprehensive short circuit, overcurrent coordination, device testing, and arc flash assessment.

- Enhancing workplace security

- Simple alternative design suggestion for the ideal shape

- Using user-defined arc fault limits, safety margins were enhanced.

- By producing arc flash labels automatically, our computer-aided analysis will save you time.

- Reduce maintenance costs and productivity declines.

Crew members are stationed in various sections of the CareLabs to ensure their availability in the event of a regular or urgent occurrence. CareLabs has quickly established itself as an ISO 9001:2008-accredited firm, thanks to the positive response from its clients. All major cities, including Hong Kong Island, Kowloon, New Territories, and Lantau Island, have access to our arc flash investigation and analysis services. Contact us immediately for a free estimate on our arc flash investigation and analysis.

RELATED SERVICES