Most electric motors are designed to run at an approx. 50% to 100% of rated load. Efficiency is usually near 80% of the rated load. The power which is consumed by the electric motor is the losses incurred in making the conversion of electrical to mechanical energy.

Hence to minimize electric power consumption, motor losses must be decreased and the electrical motor efficiency must be increased.

Care Labs helps you to perform motor start analysis to ensure that all your motors are running as per national and international standards. By hiring professionals from Care Labs you can be assured that all your motors are delivering as per the expectation and are not causing any production loss for your company.

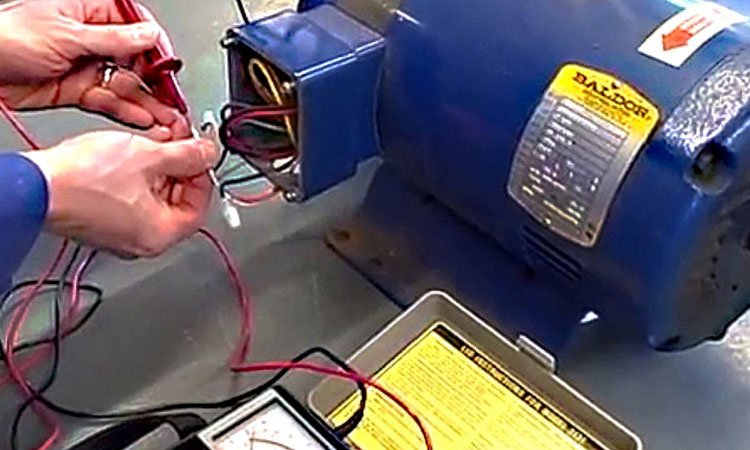

Testing and verifying of an electric motor recognize the possible voltage dip and acceleration time required for a motor and the repercussion of motor starting on the entire system. This process assesses proper initiation and running of motors on load with provided inertia without any instability or tripping.

Different other starting methods are also tested and analyzed such as reactor, auto transformer start, across-the-line, or capacitor. If any anomalies are found, Care Labs will conduct motor start analysis and suggest appropriate solutions.

Some of the common causes of motor failure are:

- Voltage imbalance

- Transient voltage

- Reflections on drive output PWM signals

- Harmonic distortion

- Operational overloads

- Sigma current

- Misalignment

- Shaft voltage

- Shaft imbalance

- Shaft looseness

- Soft foot

- Bearing wear

- Pipe strain

In the shopping complex, theatres, clubhouse, every place are now somewhere connected to the electrical system, and motor plays a major role in the electrical system. So, the motor should be maintained as per the NEC regulation code properly.

Care Labs provide services like testing and verifying the efficiency of the electric motor to companies and help them to save money by adopting all the national or international standards of safety under NEC, or NFPA 70.

After testing, verifying electrical motor efficiency is important too. It helps us to identify the faulty or corrosive part of the motor which we needed to taking action.

Steps to perform motor start analysis:

Step 1: Testing of motor analysis starts at the client site to collect all the current and historical information.

Step 2: Once all required information is gathered simulations are executed using measured data from the manufacturer.

Step 3: Using our computer models, Care Labs will be able to analyze the operation for new installations & to diagnose the problems, and recommend solutions for preexisting motor installations.

Step 4: Care Labs uses both static and dynamic methods to develop the starting sequence of your motors.

Care Labs uses the latest applications to measure speed, electrical output torque, load current, slip, and terminal voltage data at distinct time intervals from start to full speed. The study by Care Labs can help in selecting the best way to start a motor, the exact motor design required as per your business, or the needed system design to minimize the result of motor initiation on the entire electrical system.

Care Labs can help you to improve your motor efficiency as well as ensure that everything is up to standard regulations NFPA and NEC. We offer our services in California, New York, Illinois, Ohio, Texas, New Jersey, Pennsylvania, Georgia, Washington, Florida, Massachusetts, Michigan, North Carolina, New Mexico, Virginia, and all the major states and cities in the United States of America.

Contact us today to get your motor start the analysis by our experienced professionals.