One the most fatal electrical hazards that can occur at a workplace is the arc flash hazard. An arc flash fault occurs when an electrical current flowing through the air gap between conductors ionizes the air surrounding the conductor and expels large amount of energy.

Commercial and industrial electrical systems are widely prone to arc flash hazards. In the United States, it was found that on an average 5-10 arc flash incidents occurred each day causing enormous number of causalities. Over a year, the number of causalities tally to over 70,000.

The arc flash temperature ranges between 2,800 to 19,000 °C. This temperature is greater than the surface temperature of the sun (5,505°C) and can cause third degree burns which are irreversible and mostly fatal. Victims of arc flash hazard never regain their prior quality of life.

The objective and services provided by Care Labs to perform arc flash hazard analysis and mitigation are:

- Provide appropriate protective gear for persons working on electrically energized equipment.

- Evaluate the risks due to the exposure of incident energy released as a result of arc flash.

- Propose alternate protective methodologies to minimize incident energy exposure.

- Recommend appropriate arc flash hazard protection techniques that comply with OSHA, NFPA 70E, IEEE 1584 and NEC requirements.

Understanding Arc Flash Hazard:

How is it caused?

- Improper installation and work practices

- Using damaged electrical tools and equipment’s

- Accumulation of dust and debris on the conductor

- Exposed live parts and openings.

- Wear and tear, corrosion and presence of moisture

- Non periodic inspection and maintenance

- Lack of safety awareness

Effects:

Arc flash victims’ injuries are not limited to burns from the intense heat but can be a consequence of other non-thermal characteristics, such as the pressure, sound and the intense light produced by the blast.

The degree of injury is further dependent on three factors:

- Distance between the incident and the personnel

- The intensity of incident energy.

- The amount of time arc flash occurs before it is interrupted by a protective device.

Need for Arc flash study?

The primary reason to perform an arc flash hazard analysis is to increase the safety of workers and reduce arc flash incidents. Care Labs performs arc flash studies using the ETAP software.

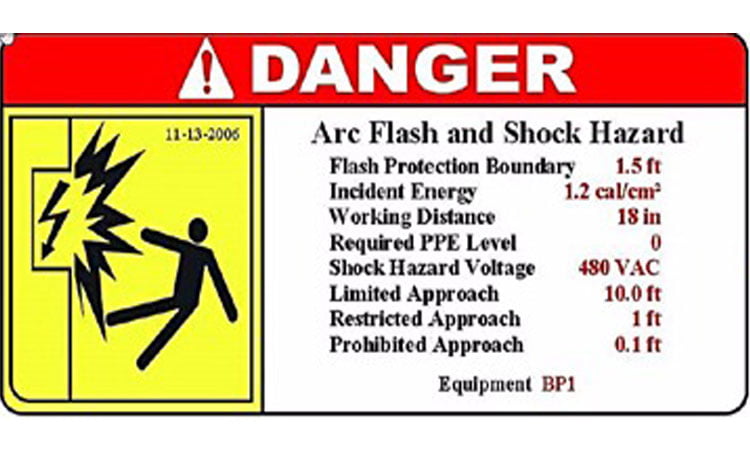

In accordance with the standards provided by NFPA and IEEE, Arc Flash Hazard Analysis performed by our experienced professionals will help protect electrical workers from arc flash incidents, aid in determining flash hazard boundary and design Personal protective equipment to minimize the degree of damage in case of an accident.

Understanding Arc Flash Mitigation

Arc flash mitigation involves taking necessary measures to minimize the risk associated with arc flash hazard. Use of personal protective equipment only helps minimize injury and does not mitigate the issue of arc flash hazard. Hence there are a series of techniques employed to minimize this damage.

Arc flash mitigation systems include and are not limited to:

- Reducing the energy level of arc flashes:

- The energy liberated by an arc flash hazard is linearly dependent on time. Hence, use of fast operating protective devices will help quickly clear the arcing fault. This is one of the most effective mitigation strategies.

- Use of over current protective devices with appropriate device setting allows reliable operation. As the setting is load dependent, it varies from equipment to equipment.

- Introducing virtual main systems to switchgears and switchboards where in you provide a digital relay with over current sensing at the low voltage side to bring down arc flash hazards.

- Employing safety measures for workers

- Use of de-energizing equipment is another arc flash mitigation solution.

- Use of infrared windows enables operators to perform operations without removing equipment covers.

- Use of temperature sensors to evaluate equipment condition and operate when the temperate crosses threshold value.

- Strictly adhering to the safe work practices and standards dictated by National Fire Protection Association (NFPA) and Institute of Electrical and Electronics Engineers (IEEE).

Care Labs offers a detailed report of arc flash hazard analysis and mitigation which includes the summary, observations, and recommendations along with all relevant drawings inscribed by our Professional Engineer. The drawings and report will also be provided to you in a digital format.

The threat of arc flash hazard from accidental contact with energized parts can be life threatening and can cause severe personal and financial loss. Companies should take additional steps to reduce the potential for an arc flash and implement solutions to mitigate arc flash hazards.

Performing arc flash hazard analysis is tedious. By hiring a professional from Care Labs, will help you take load off your shoulders and ensure that everything at your company is up to code and in line with state regulations.

Contact us to get your arc flash hazard analysis and mitigation report today!