The electrical power systems are subjected to various power quality disturbances. These disturbances aren’t new, but have always been either misinterpreted, mishandled or ignored. These issues are most prominent among equipment’s connected to the networks and industrial processes, bunted use equipment’s are equally susceptible to these disturbances.

It has become a major concern to maintain smooth operation of the equipment and mitigate power quality problems. Monitoring your power quality has several benefits, including reduced downtime and lesser utility bill.

Care Labs performs the power quality study and analysis using the ETAP– Electrical Transient Analysis Program software. It is the best software tool to carry out calculations and simulations for all components in an electrical system.

Here, we’ll address all your questions concerning power quality analysis from the basics to the benefits.

What is power quality analysis?

Power quality analysis comprises of gathering data; analyzing the data in accordance with the power quality standards and recommending appropriate solution to mitigate abnormalities in the power quality.

But what are these abnormalities and how are they caused?

There are various abnormalities affecting the power quality.

- Poor power factor – Most loads are inductive in nature. Such as induction motors, transformers, pumps, conveyers, ballasts, welding equipment’s etc. These loads affect the power factor of the system. A poor power results in high economic cost of the equipment, high losses, reduced efficiency, and poor voltage regulation.

- Harmonics – The source of voltage and current harmonics in electrical networks are non-linear loads or devices that draw non -sinusoidal currents. Harmonics result in the heating up of devices, increased losses, inefficient power consumption and resonance issues.

- Having an electrically unbalanced load – Here the load is improperly distributed across the phases leading to significant heating of the device.

- Transients: Transients are introduced by switching and arcing devices. Transients degrade the contact surface of switches, induce inefficiency in the system and lead to pre-mature failure of electronic motor drives and control.

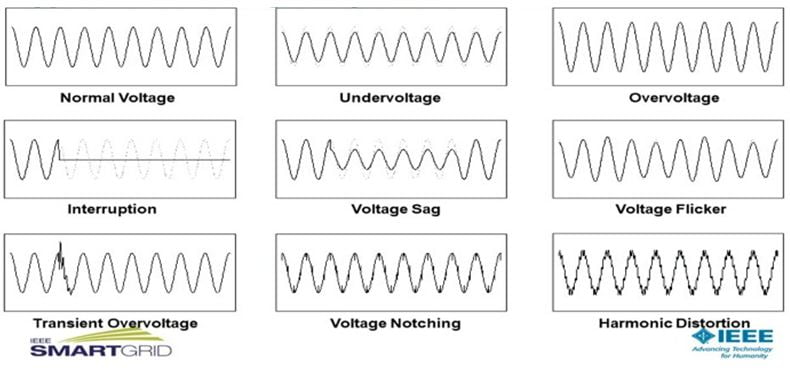

- Other causes are under-voltage, over-voltage, interruptions, dips (sags) and swells, flicker, inter-harmonics, voltage notching and rapid voltage changes (RVC)

Figure.1. Types of power quality disturbances

Steps for Power Quality Analysis

Step1: Obtaining power quality measurements:

There are various tools that can help you identify and provide data concerning your power quality issues. Equipment’s such as multimeters or DMM’s, oscilloscopes, disturbance analyzers, spectrum analyzers and harmonic analyzers help in identifying the problem and provide necessary data to isolate the problem. It is important to know where the problem is to solve the problem.

Basic measurements include –

- Monitoring quantities (Voltage/current)

- Monitoring durations of steady and disturbance performance.

- Threshold levels that differentiate steady and disturbed state.

- Sampling of waveform

Step 2: Analysing power quality measurements:

Analyzing power quality measurements has become sophisticated within the past decade. Disturbances that occur on the equipment last only for a very small interval of time (few milli seconds. Hence, it becomes mandatory to continuously monitor system performance and describe possible impacts of disturbances. The data analysis system must be flexible enough to handle data from a spread of monitoring equipment and maintain a database which will be employed by various applications.

Step 3: Fix the issue:

After obtaining comprehensive information from the above steps, it is now easier to recognize abnormalities and increase opportunities to address them before it’s too late.

The possible alternatives for solving customer power quality problems include:

- Employing power conditioning or filtering for loads that are sensitive in nature.

- Employing Central power filtering or conditioning towards the service entrance of the customer.

- For the distribution team, employing different operating procedures or modifying system design.

- Re-designing loads that are sensitive to abnormalities into loads that can withstand these abnormalities without affecting their efficiency.

Further, the requirements for each of proposed solution will be obtained and/or developed to meet the needs.

Power quality analysis’ final report provided by Care Labs will contain the executive summary, observations, and recommendations along with respective drawings inscribed by our Professional Engineer. The drawings and report will also be provided to you in a digital format. Thus, ease your process in carrying out power quality analysis.

Several companies invest in high grade quality equipment’s, but smart companies also pay attention to the quality of their power and their energy consumption. By performing power quality analysis, you’ll not only ensure safety of your equipment but allow them to run efficiently and prevent premature failures.

The checklist to perform power quality analysis is exhaustive. By hiring a professional from Care Labs, will help you take load off your shoulders and ensure that everything at your company is up to code and in line with state regulations.

Book your power quality inspection or get a quote today!