The cleanest, most cost-effective, and quickest approach to get dependable electricity is to increase energy efficiency. About 46% of the total electricity used and 69% of the total energy used in the industrial sector are accounted for by motors. One of the biggest issues facing many organizations is energy use. The insufficient architecture and power usage must be addressed first. Poor design and abuse are the main causes of high energy costs and the inability to provide the growing demand for power. Most motors operate between 50 and 100 percent of rated load, although the most efficient operation takes place around 75 percent of rated load, and efficiency tends to decline with age. An electric motor’s efficiency starts to drop automatically at 50% load.

Four Factors That Affect Motor Performance Include:

- Poor power quality has a direct impact on how well motors work since it can result in failure under severe conditions due to harmonics, transients, imbalance, sags, and swells.

- The impact of torque on effectiveness and overall performance is exhibited when a motor generates rotational force to propel a mechanical load at the rated speed of the spinning shaft. The electric motor’s dependability is ensured by operating at the stipulated frequency and torque speed. The measurement of torque gives a clear indicator of an electric motor’s health.

- The electric motor’s operational characteristics and anticipated performance: When a motor is mechanically overloaded, the coupling, bearings, and insulation are stressed, which lowers the motor’s efficiency and increases the risk of malfunction or premature failure.

- In the end, direct influence on motor function: Data collection is the initial stage in predictive and preventative maintenance.

One to six days of annual plant downtime are the consequence of 75% of industrial motor breakdowns. 90% of motor failures happened within a month after the first warning, and 36% happened in just one day. To prevent motor failure and operational issues, Regular evaluations, analyses, inspections, and audits can help reduce electrical motor issues and enhance motor performance.

Information on the Improvement of Motor Performance:

Enhance an induction motor’s performance by 68% over a 53-year period (1960 to 2013). Losses must be decreased to increase electrical induction motor efficiency over a year. The energy efficiency of induction motors has increased throughout time (data of 45 kW, 4p design motor). CareLabs tests electrical motor performance and sturdiness in a range of industrial and commercial situations. We examine and pinpoint issues to help you cut losses and boost motor performance. As knowledgeable and seasoned specialists, it is our mission to offer our clients first-rate services.

Benefits of Using CareLabs' Services:

- Always takes responsibility for their work.

- Deliver excellent customer service.

- Quick conversations answers.

- Why The inclusion of a knowledgeable and dependable electrician improves our team.

- A working knowledge of the standards.

- Choose a time for your appointment that works for you.

- Create a digital report that is comprehensive enough to meet your needs.

Methods for Conducting Electrical Motor Efficiency Audits:

- For research reasons, we compile all relevant site documentation before starting the audit.

- Create a one-line diagram and an inspection checklist to raise your ranking.

- Use the electrical motor inspection checklist to carry out the audit.

- Experts analyze and test electrical motors after finishing the checklist.

- Compile reports on electric motor inspections.

- Verify that there are no issues with power quality or load flow.

- If any issues are found, our expert will see to it that they are fixed.

- Verify that your engine complies with national efficiency regulations.

- Offer a report in digital form along with suggestions for safe work practices.

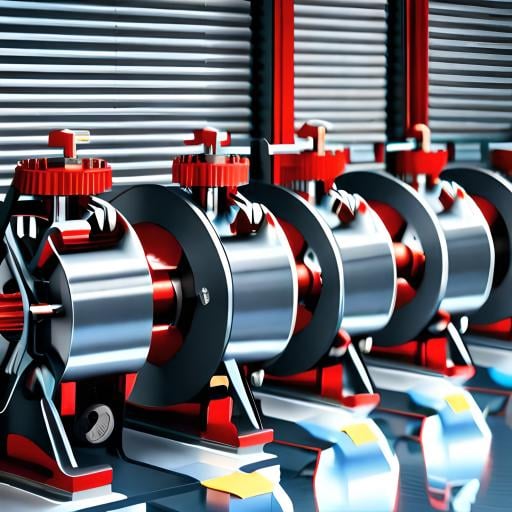

CareLabs offers motor acceleration studies to make sure the motor functions properly under situations of high load and to boost productivity (by mitigating the losses). Motor dependability is increased by reducing losses. In every major German city, including Berlin, Hamburg, Munich, Cologne, Frankfurt, and Stuttgart, we provide motor start analysis services. For further details and a price quotation on the efficiency audits of commercial electric motors, get in touch with CareLabs.