Chinese Arc Flash Analysis: A Comprehensive Guide

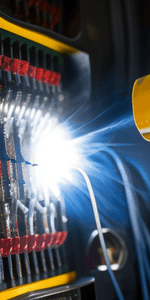

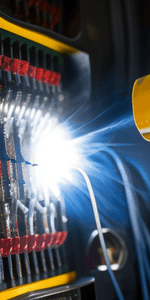

Electrical arcs develop when a gas is subjected to a voltage larger than its insulating capacity. When the voltage is high enough to ionize the space between the conductors, the arc begins. When gas is ionized, it becomes an excellent conductor, enabling current to flow and creating the arc-shaped current known as an arc flash. An arc fault is an unintentional electrical discharge that results in a fire.

- Arc flashes produce high heat, which results in dazzling light and a loud boom.

- An arc blast is a high-pressure wave that can discharge shards and molten metal.

- Poisonous vapors

Arc flash risks have the potential to severely damage electrical infrastructure and company operations. The following business losses are caused by arc flash hazards:

- Additional spending for medical treatment, therapy, and workers’ compensation, as well as costs associated with accident investigation and lost productivity.

- Dispute-related legal fees and judgments, penalties, insurance premiums, and expenditures involved with replacing and repairing persons.

- unfavorable influence on the business’s brand and reputation.

- A loss of economic possibilities is caused by a history of accidents that might result in the revocation of an electrician’s license.

Table of Contents

Electrical Arc Flash Results In:

- Visible organs on a circuit whose insulation have failed

- Human irresponsibility

- Poorly maintained switches and circuit breakers

- When there is water near to the device, there is cause for concern.

- Unplug any panels that are obstructed.

- Installation of wire for high voltage

- Ionization releases defective equipment and tools

Technique for Arc Flash Analysis:

Whenever high-voltage or low-voltage, high-current switching occurs, an arc flash is potential.

First Step: Determine the arc flash danger:

- Perform an arc flash/fault analysis or study, including data gathering, software-based power system modeling, short circuit analysis, overcurrent protective device coordination study, arc flash analysis, and arc flash assessment.

- Evaluation of a worker’s probable arc flash exposure

Second Step: Manage the threat:

- Only working with deactivated equipment to reduce worker exposure to arc flash threats.

- Manual systems should be replaced with automated ones.

- To protect employees from potential dangers, erect physical barriers between them and powered machinery.

Third Step: Engineer management:

- Reduce short circuit current to decrease incident energy.

- Equipment for arc flash detection and suppression

- Incorporating and remote controls

- Upgrades or changes to the switchboard

- Permanent circuit breakers installation

- Insulating material for bus bar

- Repair of blown fuses

Fourth Step: Controls over administration:

- Creating labels for plants, switch rooms, and other sites to measure incident energy levels is the fourth step of administrative controls.

- Circular borders.

- Arc flash documentation and data collection.

- Implementing protective procedures and criteria to reduce exposure

- Providing preventive measures to reduce PPE (Personal Protective Equipment) levels and incident energy implementation.

Fifth Step: Personal protection equipment (PPE):

- Personal protective equipment can reduce the severity of an accident but cannot prevent it. Despite being the least effective, it can reduce the severity of an injury. The sort of personal protection equipment (PPE) utilized is determined by the severity of the occurrence.

CareLabs offers a remedy for every danger associated with arc flashes. Assessing arc flash hazard hazards and implementing appropriate mitigation and control measures to protect your employees and property is the responsibility of professionals with the requisite knowledge and abilities.

CareLabs Service Benefits:

- Electrical systems that are safer and compliant with regulatory norms.

- Fully integrated power systems save both time and money.

- Establish a more secure workplace.

- Provide easy-to-implement solutions when a circumstance calls for them.

- Increase the margins of safety.

- By producing arc flash labels and work permits automatically, you may save time.

- Avoid penalties and legal charges.

This proposal focuses on the accumulated knowledge and experiences about the dangers posed by electric arc flash. It describes the control structure for arc flash management. In its list are de-energizing electrical equipment, IR thermography, racks, and further arc flash management measures. CareLabs has personnel stationed in many areas to ensure that our specialists are available in case of a regular or urgent emergency. While swiftly establishing itself as an ISO 9001:2008-accredited organization, CareLabs has amassed a clientele with a compelling reputation and excellent evaluations. CareLabs provides arc flash investigation and analysis services in several major cities, including Beijing, Shanghai, Guangzhou, and Shenzhen.

RELATED NEWS

Coordination

RELATED NEWS