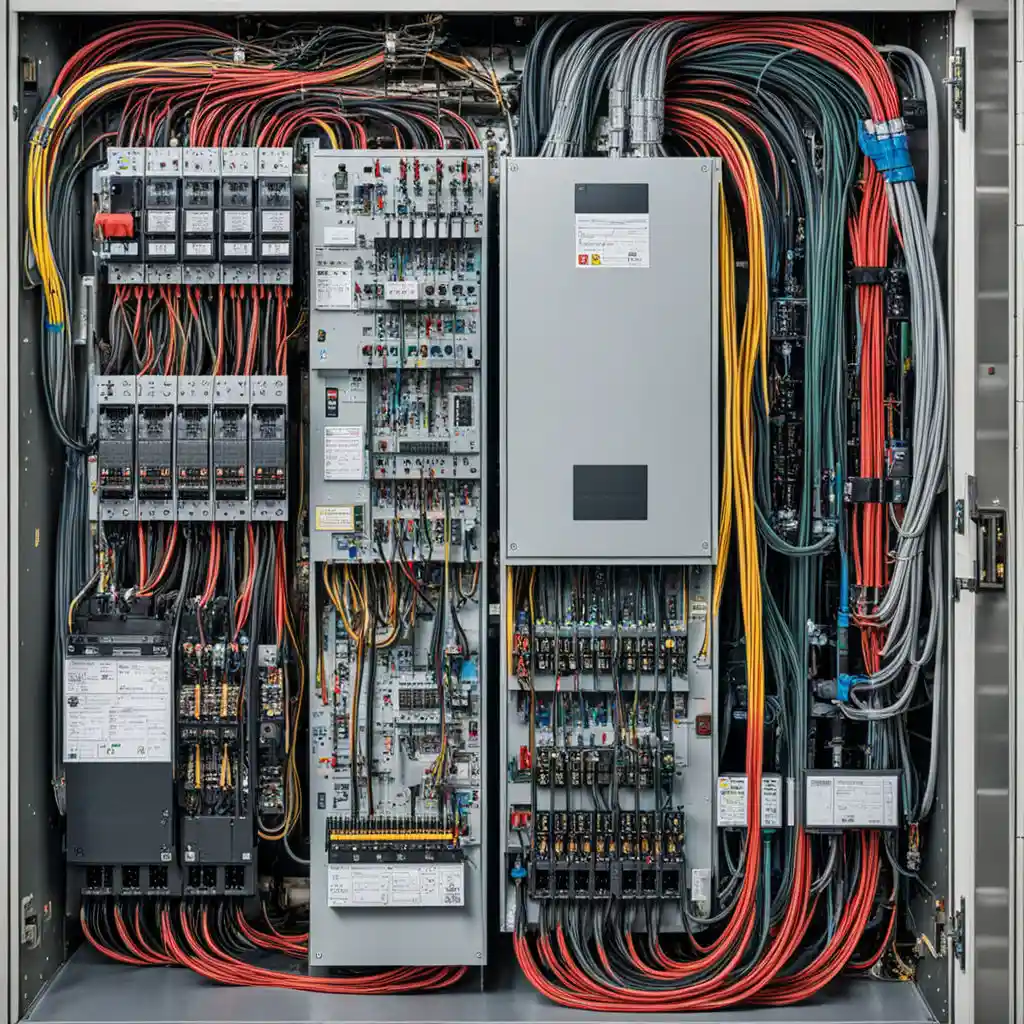

The word “Arc flash” looks so simply, but it is devastating and dangerous with its consequences. In this article, we learn more about the importance of Arc Flash Analysis.

If you are in confusion about whether you should take an arc flash analysis or not, then you are in the quiet right place. It is not only harming the employees of your facilities, but it may also destroy or damage the costly equipment or devices and may lead you to financial losses.

What is Arc Flash?

An arc flash can also inflict financial havoc in the forms of damage, lawsuits, fines, and destroying expensive equipment and devices. In annually, approximately 200 arc flashes occurred in Canada that why performing an arc flash analysis can help you to avoid further incidents. You may be familiar with the knowledge of arc flash incidents, and it is the unfortunately major cause of electrical injury in industrial plants and facilities. Arc flash causes severe damage, injuries including eyesight loss or third-degree radiation burns, and sometimes deaths.

Arc flash—- a fiery explosion that can results in a short circuit in high-power electrical devices and a common cause of several deaths of workers due to electricity in Canada every year, and many more are permanently injured.

Arc flash can reach 5000-degree Fahrenheit, which is four times hotter than the sun’s surface and can be extremely hazardous to workers around the electrical installation incident.

In this era, arc flash mishap incidents go high, and one of the major causes behind this is transient (voltage spikes), resulting in switching reactive loads or lightning strikes.

See related article in here: Importance of Arc Flash Hazard Analysis and Mitigation Canada

Arc flash can also be occurred due to any of your negligence, such as the buildup of conductive dust, corrosions, improper work procedures, dropped tools, and accidental contact with electrical systems. An arc flash lasts until the overcurrent protectant devices open the circuit, or the at least two cycles completed (0.03 sec) to six cycles most (few milliseconds) by that time the damage has already happened. According to act CSA Z462-15, 4.3.5 1b, periodic inspection of an arc flash must not exceed more than five years. A simple arc flash study and analysis, improvement in safety awareness, or study can help you avoid arc flash hazards.

Consequences of Arc Flash

You know, according to the Associations of Workers Compensations Boards of Canada, annually, six to eight hundred people encounter electrical workplace incidents. People suffered from serious injury burned 255, while 28 were dead. However, 21% of death in electrical-related facilities and 79% of death were involved in other occupations (Resource WHSC).

In March 2000, an industrial maintenance electrician Richard Burgess was doing his routine work and suddenly an arc flash occurred which cause a large part of ground wire copper splatter onto his body. Burgess suffered severe burns to his face and hands. The safety manager of organizations that employ people to work near electrical equipment must follow CSA Z462, Workplace Electrical Safety. So, “what are you thinking about?” call today to know more about arc flash study and analysis service.

Care Labs Solutions:

Care Labs perform arc flash study and analysis to avoid the harm that may occur due to arc flash. We complying the Canadian Electric Code (CEC) for your safety against danger and law act (CSA Z462-15, sections 4.3.3, 4.3.4, and 4.3.5).

Step by Step Guide to Perform Arc Flash Analysis:

Phases for completing successful arc flash analysis:

- Gather all distribution system-related data and start field survey.

- Create an electrical one-line diagram.

- Using Computer ETAP software, build a one-line diagram and performs all the necessary assessments.

- After the analysis, we started to create a draft, which we issue clients for review and comments.

- Identify the electrical equipment that failed and issue a final report, incorporating the comments.

- Print arc flash labels on self-adessive electric paper.

- At last, Care Labs suggest mitigating issues.

Several industries avoid risk and chooses safety by calling Care Labs then why not you. It’s your responsibility to choose what is right for your facility. Care Labs believes in customer safety and client satisfaction. Our primary purpose is to focus on the safety of your employees and equipment. We value your time.

The Canadian Standards Association’s CSA Z462 is Canada’s version arc flash standard of NFPA70E. Released in 2008. The Institute of Electronics and Electrical Engineers IEEE 1584 – 2002, Guidelines to practicing Arc-Flash Hazard Calculations. Care Labs provide arc flash assessment, study, and analysis all over Canada. We help you to analyze the risk of arc flash hazards and assist you in mitigating the risks. Contact us to know more about arc flash study and analysis services and get a quote.

Safe and Sustainable Hydropower in Canada

Hydropower in Canada- Past, present, and future! Imagine a world where 60% of the power demands are met by renewable energy sources. Wonder not, because it is a reality in Canada where hydropower is the star. Over a century ago, Canada took its first strides toward becoming a global leader in sustainable hydropower. As time […]

Cost Effective Arc Flash Study in Canada

The importance of arc flash studies in Canada’s robust manufacturing and energy sectors cannot be overstated. Why? Because it evaluates the risks associated with any electrical system. It is a core element to ensure the safety of personnel and equipment in a facility. Traditionally, it involves significant manpower, time, and resources. Enter Carelabs, a pioneer […]

The Role of Short Circuit Analysis in Enhancing Workplace Electrical Safety

Introduction Canada has one of the world’s most robust workplace electrical safety regulations. The Occupational Health and Safety (OHS) summarizes employers’ and supervisors’ rights and duties. Short circuit analysis identifies potential fault sections and their consequences in complex electrical systems. This helps develop a proper protection strategy and thus contributes to workplace electrical safety. Let […]