Assessing And Lowering the Danger of an Arc Flash Is Crucial:

Electrical arcs may develop when a gas is exposed to a voltage that is greater than the gas’ insulating capacity. An arc will occur when the voltage is high enough to ionize the space between the conductors. Ionized air transforms into a superb conductor, allowing electricity to move. Ionization of the air results in a current that generates heat and bright light.

The phenomena get its name from the way this heat causes the ionized air to rise and form an arch-shaped current. The temperature of an arc flash may reach 20,000 degrees Celsius.

Arc flash hazards put people and property at peril. Among arc in flash’s effects on business are:

- The cost of worker compensation, medical attention, rehabilitation, accident investigation costs, and lost productivity are all examples of direct expenditures.

- Legal and judgment fees, litigation costs, fines, insurance premiums, repair costs, and replacement worker fees are examples of indirect expenditures.

- Negative implications include the possibility of facing criminal charges, your personal reputation, and your ability to compete on the employment market.

- Clients often reject companies with high incident rates, which results in lost business opportunities and perhaps the license revocation of an electrical contractor.

- Accidents involving electrical circuits Flash often leave a negative image, leading to lost opportunities and money spent.

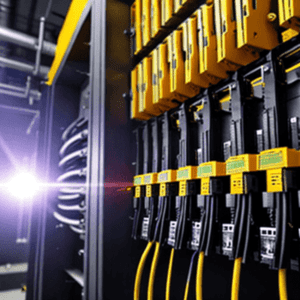

Risk from Arc Flash Causes:

- Using the wrong surface for the probe

- Improper installation, equipment, and methods

- The use of faulty electrical components

- Equipment gaps or damage to the insulation

- Disconnect any faulty panels.

- Dust on electrical equipment or corrosion

- Improper switch and circuit breaker maintenance

- Faulty parts or frayed connections

- Wires with a high voltage or a constant supply of power

- Moisture in electrical equipment

Techniques for Reducing Arc Flash Hazard:

Switching Off Electrical Devices:

It reduces possible risks as much as is practical. Avoid working on electrified equipment and use extra care while testing or re-energizing de-energized equipment. Using remote tracking technology, circuit breakers are maintained away from arc flash boundaries that may endanger their users.

Make Use of Low-Risk Technology:

Arc flash analysis and power system studies are carried out to identify the risks connected with short circuits and the coordination of protection devices. Protect people and property by using low-threat alternatives, such as remote rack equipment.

Redesign of the Electrical and Control Systems:

Make sure that you have access to the level of PPE (personal protective equipment) necessary by the arc flash danger category. Engineering tools and practices are being modified to reduce risks. Energy distribution systems and breakers are designed to reduce incident energy.

Lower the Available Fault Current Level:

Circuit breakers without current limits will aid industry in reducing fault current availability. For maintenance, these devices may be used with an open tie. By reducing the amount of accessible fault current, opening the connection between dual power feeds during maintenance reduces the risk of an arc flash. By creating an obstruction in the passage of electrical current, current limiting reactors may successfully stop current flow during arc faults.

Change the Energy of the Blaster:

Support the use of arc-resistant materials. Arc flash energy and heat are channeled via ducts to an unoccupied area using arc-resistant switchgear, which uses sealed joints, pressure relief vents on the top, and stronger hinges. CareLabs does in-depth arc flash analysis. Arc flash threats are assessed by experts to update your safety program. CareLabs can locate and put into practice cutting-edge arc flash risk reduction techniques. CareLabs may conduct research and put cutting-edge arc flash danger reduction technologies into practice. ETAP (Electrical Transient Analysis Program) software is used by CareLabs for research and analysis.

To ensure that our expertise is accessible in both routine and emergency circumstances, we include crew members in several locations. We quickly attained ISO 9001:2008 certification and loyal clients. We provide our services throughout Buenos Aires, Córdoba, Rosario, and Mendoza in Argentina.

LATEST NEWS

Harmonic Study &

Analysis