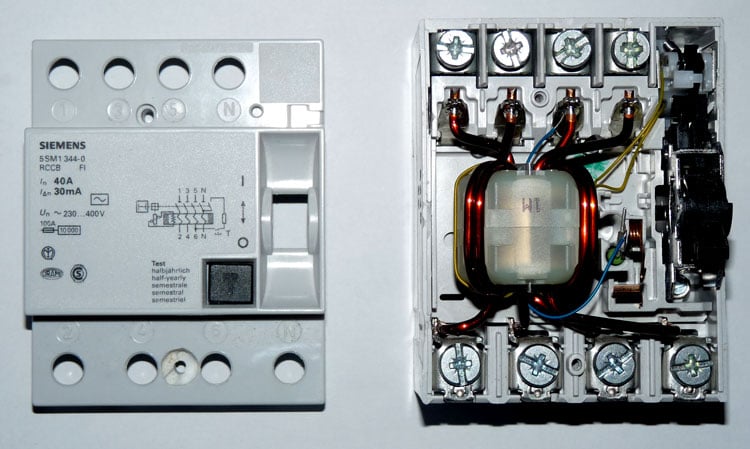

Residual Current Devices, or RCDs. are safety switches that prevent people from getting electrocuted in homes and businesses. The device monitors the flow of electricity as it enters a property from the main distribution panel. A surge of electricity, or an imbalance of electrical power, can cause injury or death. If an imbalance in electricity is detected, the switch automatically cuts off the electricity. The installation of at least two RCD Safety Switches in a building allows the electrical circuits to be evenly divided. That increases safety two-fold by preventing electrocution, and allowing some lights and power to remain on in the building.

A Residual Current Device is designed to protect against the risks of electrocution and fire caused by earth faults. For example, if you cut through the cable when mowing the lawn and accidentally touched the exposed live wires or a faulty appliance overheats causing electric current to flow to earth. RCD’s are very sensitive and will activate within 10 to 30 milliseconds stopping the flow of electricity.

How Often Should RCD Testing Occur?

RCD testing has to be completed every three months, and documented, to remain in compliance. There is a test button on the device that has to be pressed to determine if the switch is working correctly. It is working properly if the power goes off. If the power does not go off, an electrician has to be called to re-test the switch, repair it, or replace it. It is strongly recommended that all homeowners, even those not selling the property have the devices installed for safety. The cost of installing residual current devices is nominal, especially compared to the safety of family members.

Why Test Residual Current Devices?

Some electrical appliances and old wiring may have a normal small amount of earth leakage which can trip a RCD.

Earth leakage increases with each additional electrical appliance that is plugged in, and if RCD keeps tripping out it may be an overloaded circuit. Any faults we recommend that you have your wiring and appliances checked by an electrician to ascertain the fault if a RCD keeps tripping.

The majority of electrical fatalities could have been prevented by the use of a properly installed RCD, and regular testing to ensure they are working correctly.

If maintained correctly an RCD can not only help to prevent fire due to appliance or wiring faults, they save lives. Thermal Scanners help clients to ensure their RCD’s are compliant and tested in line with the UAE Standards.

What is Done During Testing of RCD?

The effectiveness of the RCD must be verified by a test simulating an appropriate fault condition and independent of any test facility, or test button, incorporated in the device.

Tests are made on the load side of the RCD between the phase conductor of the protected circuit and the associated cpc. Any load or appliances should be disconnected prior to testing. RCD test instruments require a few milliamperes to operate; this is normally obtained from the phase and neutral of the circuit under test. When testing a three-phase RCD protecting a three-wire circuit, the instrument’s neutral is required to be connected to earth. This means that the test current will be increased by the instrument supply current and will cause some devices to operate during the 50% test, possibly indicating an incorrect operating time. Under this circumstance it is necessary to check the operating parameters of the RCD with the manufacturer before failing the RCD test, the manager must reset the device by pressing the appropriate button. Thermal Scanners is able to carry out all your RCD Testing requirements and upon completion, issues you with a Comprehensive Report and Compliance Certificate.

How are RCDs Tested?

The wiring regulations require the residual device providing additional protection to disconnect within 40 milliseconds when tested at 5 times the current they are designed to operate within normal circumstances. This is something our electricians test using calibrated equipment and not something the facility owner can do. It is one of the tests carried out during an electrical inspection and confirms if the RCD would disconnect in the necessary time to prevent shock.

If you are not sure when the RCDs within your installation have been tested, get in touch with us to make an appointment for us to test them for you. All electrical equipment will need to be turned off prior to RCD Testing being carried out.

Each RCD Test only takes approximately 5 minutes for each RCD. We suggest that RCD Testing is carried out after hours, before the office opens, or you will need to advise your staff that the power will be disrupted for each circuit, and that there computers will need to be turned off.

Different types of tests are:

- Operating Time Test: This test measures how long the RCD takes to trip, indicating whether it is fast enough be effective.

- Push-button Test on RCDs: The push-button test is to ensure that the RCD will trip when there is an earth leakage, and break the electrical circuit protecting the individual from suffering an electric shock, or electrocution. This test should be performed daily or before each time you use the RCD – whichever is the longer.

- Trip time test: The “trip time” test using the “applied current” method is a far more accurate means of testing RCDs. It measures the actual trip time and must be performed with equipment able to measure this to within 0.008 of a second.

- Portable RCDs: Portable RCDs requires the use of an isolation transformer.

Below are the Steps Done for Testing RCDs

- Plug a small lamp into a power point and make sure it works. Leave it turned on.

- Make sure that electricity is connected to the property and the main switch is in the “on” position. The lamp should be on.

- Turn off all electronic equipment (computers and televisions) etc.

- Push the test button on each RCD. Do not hold your finger on the test button. The RCD should operate (turn off). If it does not operate, it must be checked by an electrical contractor.

- After pushing the test button and the RCDs have turned off check that the small lamp is now off. Also check that all the lights and power points do not operate. To do this, plug the small lamp into all the power points and turn the power point on. If the lamp turns on, a licensed electrical contractor must be engaged to correct the wiring.

- When finished testing, turn the RCDs back on and check that the lamp works when plugged into a power point.

The owner of the RCD must keep records of RCD testing, except for the daily push button testing of portable RCDs. The OHS Regulation requires that a record is made and kept of all inspections, tests and maintenance carried out on electrical equipment. We will provide you with Report that will have a detailed record of the tests that we do and its result.

Benefits of RCD Testing

A tested RCD can help put your mind at ease when it comes to the safety of your workers. RCD testing performed by a qualified professional can ensure that your RCDs have no faults in them and can be relied upon to function when needed. Some other benefits of RCD testing are:

- Compliance with safety standards

- Cost savings

- Early detection of faults

Manufacturers recommend that portable RCDs are tested every time you use them.

Carelabs is authorized provider of Electrical Installation’s Study, Analysis, Inspection, and Certification services in UAE, and conduct Residual Current Device Testing service in UAE.